Turnkey, Custom-Engineered Solutions

Enhanced safety

Reduced turnaround duration

Lower costs

A single point of contact and responsibility

Reduced offsite exposure and transportation risks

Minimized handling damage

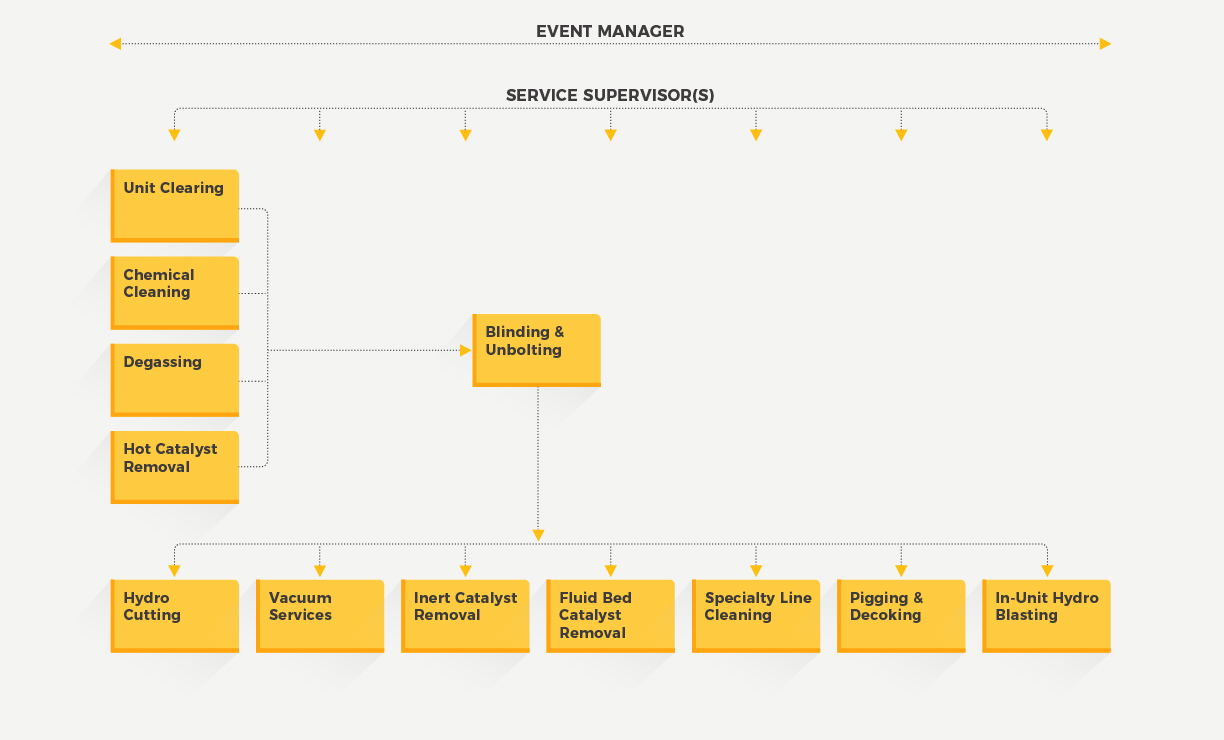

Turnaround Management & Service Line Capabilities

- Unit clearing

- Chemical cleaning

- Degassing

- Hot catalyst removal

- Fluid bed catalyst services

- Fixed bed catalyst services

- Inert catalyst services

- In-unit 10-40,000 psi hydro blasting

- Pigging and decoking

- Precision hydro cutting

- Vacuum services

- Specialty line cleaning

- Specialized FCC unit services

- Specialized Coker unit services

- Automated technologies for all units

- Water recirculation for hydro blasting and pigging & decoking

- Flareless turnarounds for all units

- MSS vacuum trucks for all units

Unique Resources, Superior Results

Turnkey, Multi-Service

We provide the broadest range of specialty, high-value service lines and the ability to execute a larger scope of turnaround services. We also handle routine tasks, such as moving and connecting hoses, so your personnel don’t have to.

Best-in-Class Safety

We operate according to the industry-leading safety guidelines. We develop project-specific safety plans incorporating both customer and USA DeBusk guidelines, make extensive use of automated technologies, and have dedicated Safety professionals onsite at all times.

Strategic Planning

Our Event Manager and turnaround teams work with your engineering, operations, maintenance and HSE personnel to clarify the scope of work, identify potential problems, and develop safe, effective solutions to meet your objectives.

Synergy

With the ability to command multiple service lines and resources, we take advantage of efficiencies in utilizing equipment and personnel, saving time, reducing costs, decreasing our overall footprint, and ensuring consistent, quality results.

Event Management

A highly experienced Event Manager participates in the the earliest stages of turnaround planning, provides top-level management, coordinates field-level supervisors, and streamlines customer communications.

Automated Technologies

Extensive automation throughout our service lines increase speed, improve precision and productivity, and mitigate safety risks.

Sustainability

Our procedures protect people and the environment. We offer enhanced containment, water recirculation and on-site filtration technologies to conserve resources and reduce waste.

Safety

We develop a project-specific safety plan that incorporates both customer and USA DeBusk guidelines.

As a multi-service-line provider, we are able to establish and enforce more consistent safety practices for all work.

Top level participation, including senior USA DeBusk management and Event Manager

Safety trackable QR codes on each employee ID badge link to cloud-based records of certifications and training; customers can check the status of any employee in real time

Safety professional(s) on-site full time

Automated technologies reduce risks

Specialty Service Highlights

Unit Clearing

Opens the unit efficiently, saving days on the turnaround critical path

Safe for personnel and equipment

Pre-engineering to develop detail drawings and timelines

Proven, predictable results

Hot Catalyst Removal

1,250°F (677°C) vacuum technology

Eliminates cooling time

Savings on catalyst purchase and disposal

Operational yield support, transloading

Inert Catalyst Services

Safety innovations include real-time biometric monitoring

Catalyst Removal Amphirol (CAROL), the only robotic solution in the U.S. for unloading catalyst from inert reactors

Cardox CO2 gas expansion fracturing to dislodge fused catalyst

Vacuum units and other equipment purpose-built for catalyst handling

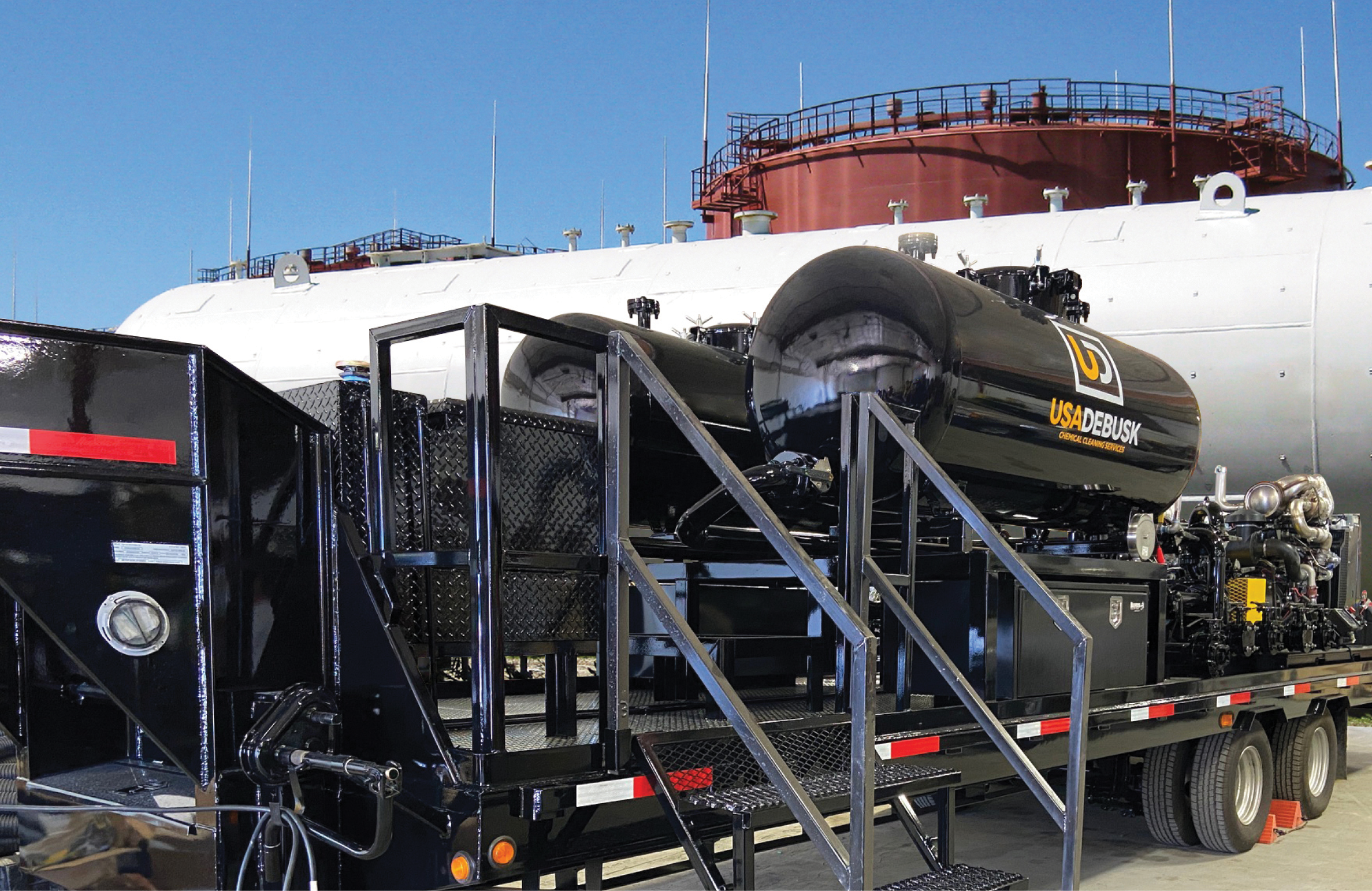

Pigging, Decoking & Filtration

World’s largest fleet of TriMax™ triple pumping systems that increase productivity by 50%

Advanced electronic controls, automation and video monitoring

The industry’s most diverse selection of decoking pigs

Closed-loop effluent filtration

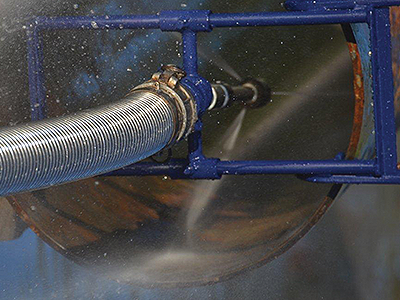

Specialty Line Cleaning

Automation for safety and productivity

Custom engineering to apply properly sized hoses, nozzle configurations, pressures and cleaning speeds for each line

Containment of coke and water

Highly trained personnel

Hydro Cutting

40,000 psi water

Fully automated operation

Specialty tracks

Dedicated hydro cutting teams

Hydro Blasting

Units up to 40,000 psi

In unit and pad

Automated technology

lab management